|

| HOME | THIS ISSUE | CALENDAR | GRANTS | BACK ISSUES | < BACK | NEXT > |

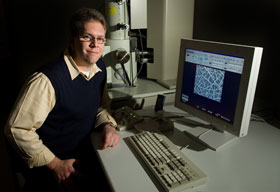

Chemistry professor develops fiber that changes colorsby Michael Kirk - June 19, 2006 |

||||

|

Those bleary-eyed commuters who get dressed each morning in dim light only to realize later that their tie doesn’t go with their suit or their socks don’t match their pants may have nothing to worry about a few years from now, thanks to research by Gregory Sotzing, an associate professor of chemistry. He has developed a fiber that can dramatically change color at the flick of a switch and, he says, can eventually be made into thread to create washable articles of clothing that could change from one color to another at the whim of their owner. “We’ve been working on this for three years, and this really opens the door for the revitalization of the fiber industry,” Sotzing says. The material he has developed consists of electrochromic polymer fibers that can be formed by conventional spinning processes. When developed into thread and woven together with tiny wires, these fibers can form a garment. Electrochromic polymers have color because they absorb light. Changing the voltage between the wires causes them to absorb light differently, so the color changes. The clothing would be divided into pixels that could change color when applied to an electrical field operated by a simple battery pack. When the voltage was reversed, the threads would revert to their original color. A T-shirt could change from blue to red, for example, in milliseconds.

“This is the first long fiber prepared by conventional spinning processes that has the ability to change color,” says Sotzing. “The difference between these advances and previous work is that none of the fibers created in the past were long enough to be made into threads. We have the potential to make the fibers as long as one kilometer. We have already made fibers several inches long.” It would also be possible to change clothing into a color that matches your surroundings, giving it a chameleon-like quality. This prospect has been of interest to the U.S. military for the past couple of decades, because of the advantage of having uniforms that could adapt to the surroundings. Sotzing says he is still working on creating a material that can go through a wash/dry cycle. “If money wasn’t an issue, a fabric display could be produced within the next four years,” he says. The research was funded through the National Science Foundation and was published in the journal Advanced Materials, patent pending. |

| ADVANCE HOME UCONN HOME |