For more archives, go to the Advance Archive/Search Page.

Time Delays May Help, Not Hinder,

Computer-Controlled Systems

When seconds count, waiting too long may mean disaster. But Nejat Olgac has discovered that in certain circumstances, time delays in computer-controlled systems may not be detrimental, but may actually improve performance.

|

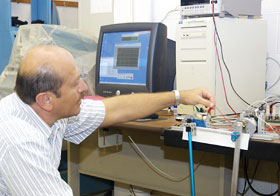

Nejat Olgac, a professor of mechanical engineering, uses a time-delay device in his lab. Olgac's research suggests that time delays in computer-controlled systems may be beneficial.

|

Olgac, a professor of mechanical engineering, conducts research on computer controlled systems such as missile guidance, space systems, and manufacturing machinery.

In a controlled system, there is always some delay between the receipt of information and the system's response. It may be measured in microseconds (as in data conversion from analog to digital form) or up to a few seconds (as in digital vision, object recognition, and GPS measurements).

But although time delays in many cases cause the performance of the control system to deteriorate, often to unacceptable levels, Olgac and his research team have discovered, through complex mathematical calculations, that under some circumstances, systems can be controlled as accurately with data traditionally considered "old" as with up-to-date data.

Time delays increase the complexity of the system, and when the sensory information that is used in the control logic is hampered by multiple delays, the task becomes more difficult to accomplish.

Take, for example, a computer-guided missile tracking a target. The delay in receiving information about its position is compounded by another delay for velocity, making the rocket much harder to control.

Most events - both those involving machines and those involving humans - are governed by slightly delayed information. When a person is driving a vehicle, for example, there are time lapses between seeing an obstacle, recognizing it, and taking corrective action.

What instinct suggests - and what scientists have believed until now - is that with each delay, control gets worse and worse. However, evidence gathered by Olgac and his team essentially shows the opposite, at least in some cases.

"The control performance may improve, in some instances, with use of older data," Olgac says.

Because of this finding, Olgac has proposed intentionally prolonging existing delays in order to enhance the performance of some control systems. "Following a counter-intuitive approach, we can prolong the time delay in the available data - because obviously, we cannot make it shorter - in order to improve the controllability," he says. "We call this 'delay management'."

Olgac's research group recently received grants from the National Science Foundation and the Department of Energy to study the practical impact of this newly discovered phenomenon. The findings could have a broad impact on a variety of applications in biomechanics, space systems, vehicle systems, robotics, and machinery, and also in regard to living things.

"There are interesting repercussions of such a breakthrough in many areas," Olgac adds. "Human cognitive delays and circadian studies (sleep deprivation and functioning when sleepy), and insect colony multiplication trends, for example, are all governed by similar fundamental dynamics that are related to the influence of delays in the events."

Researchers in the Advanced Laboratory on Automation, Robotics, and Manufacturing (ALARM Lab) associated with the UConn's mechanical engineering department, recently developed a delay-scheduling technique to determine whether there is a specific time delay for optimal performance. They also developed a variety of delay settings to enhance the effectiveness of control.

"The ALARM Lab has experiments demonstrating this capability on a robotic structure, and in animated games," Olgac says. "A patent application is pending on 'Optimized Simultaneous Machining,' where multiple machine tools operate simultaneously on a single work piece. The process is very common today, but it is performed in sub-optimum fashion. The patent will translate our new 'delay management' concept into machine tool productivity increase."

Olgac is confident that the difficult mathematical calculations underlying his findings are "airtight." He says some other researchers in the field have hailed his work as "a major result destined to close the gap between decades of theoretical studies and practical knowledge."

Last week, he gave an invited presentation on his findings at the International Federation of Automatic Control's 5th Workshop on Time-Delay Systems in Leuven, Belgium, a gathering that brings together the world's top experts in the field.

During his stay in Europe, he also gave seminars at Aachen Technical University's world renowned Machine Tools Research Laboratory, and at the Free University of Brussels. He also held a prestigious guest editorship for a recent special issue of the American Society of Mechanical Engineers' Journal of Dynamic Systems, Measurement and Control, which was dedicated to Time Delayed Systems.