|

This is an archived article.

For the latest news, go to the Advance

Homepage

For more archives, go to the Advance Archive/Search Page. |

||

|

Smile!

Dental Clinic Taps Improved

Technology to Provide Better Crowns By Patrick Keefe

Technicians in the prosthetic lab at UConn's School of Dental Medicine are using computer-assisted drafting - computer-aided manufacturing (CAD-CAM) - to make virtually perfect dental crowns.

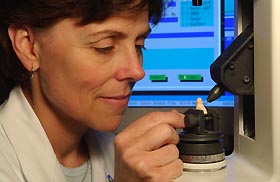

Perfect crowns mean a perfect fit, and that means perfect smiles. The lab uses a commercial process from Procera, a business enterprise from Nobel Biocare of Sweden. The process includes computers and equipment that allow individual labs to order online from a centralized manufacturing facility in New Jersey. Advantages of the lab include high-quality, high-strength products and an expanded and highly aesthetic product line. Ordering online also allows the lab to do other work while Procera is manufacturing the prosthesis. Precision Job Karlsrud's lab works with general dentists but also dental prosthetic specialists to make caps and crowns, bridges, dentures, and implants. The dentists supply the lab with an impression of the teeth they have prepared, from which the lab makes a gypsum model called dental distone and then develops individual dies of the teeth they are going to be producing. If the Procera system is used, a technician takes the die and mounts it on a computerized rotating platform. A laser pinpoints the top center of the die and as the die spins, a stylus with miniscule tolerances traces it. The computer takes the information from the tracing, digitizes it, converts it into a three-dimensional model, and then sends it to the plant in New Jersey. Computerized manufactories there take the information and turn out the aluminous oxide crown, which is then packaged and sent to Connecticut. The turn-around time is within four days. Practical and

Pleasing "It's a good, relatively straightforward process," he says. "The preparations are not complicated, and it's a strong, aesthetically pleasing and modern restoration. I think in the future this process will be in widespread use." Dr. Rachel Squier, an assistant professor of prosthodontics and operative dentistry, says many clinicians like the system for technical as well as aesthetic reasons. "Procera is user-friendly to dentists," she says. "There's not a lot of difference in the preparation, it requires the same general procedures. Many patients prefer it because it is an all-porcelain restoration, and some don't want metal in their mouths. Clinicians like the products because they're easy to use, they're durable, and they're strong." There's a practical commitment to the system as well. "I like them," says Karlsrud, the director of the UConn lab. "I've got a couple of Proceras in my mouth and so does my wife. They look great and neither of us has had any trouble with them." |

omputer technology can do lots of things, including make

your smile brighter.

omputer technology can do lots of things, including make

your smile brighter.